전송 중 전자 현미경(TEM) 분석 합리적으로 해석 가능한 고품질 이미지를 얻는 데 가장 중요하고 기본적인 단계는 샘플 준비입니다. 부적절한 샘플 두께, 낮은 전도도, 또는 샘플 준비 중 발생한 손상은 비정상적인 전자빔 투과, 이미지 왜곡, 심지어 샘플 폐기로 이어질 수 있습니다.

TEM 샘플 요구 사항

① 시료는 일반적으로 두께가 100nm 이하인 고체이어야 합니다.

② 전자현미경 전자기장의 작용으로 샘플이 빨려나와 폴슈에 부착되지 않습니다.

③ 시료는 고진공에서 안정성을 유지할 수 있습니다.

④ 시료에 수분이나 기타 휘발성 물질이 포함되어 있지 않은 경우, 먼저 건조해야 합니다.

둘째. 대량 샘플 준비

대량 샘플의 준비에는 일반적으로 전해 이중 분무, 이온 희석 FIB가 포함됩니다. 초박형 또는 동결 슬라이싱을 사용하여 100nm 이하의 박막 샘플을 준비한 다음 테스트를 진행합니다.

① 전해 이중 분무

전해 이중 분무법은 공정이 간단하고 조작이 간편하며 비용이 저렴합니다. 중앙의 얇은 영역이 넓어 전자빔이 쉽게 투과됩니다. 하지만 시료는 전도성이 있어야 하며, 시료를 만든 후에는 즉시 꺼내 증류수로 여러 번 헹궈야 합니다. 그렇지 않으면 전해질이 얇은 영역을 계속 부식시켜 시료를 손상시키고 심지어 쓸모없게 만들 수 있습니다. 전자현미경으로 적시에 관찰할 수 없는 시료는 글리세롤, 아세톤 또는 무수 알코올에 보관해야 합니다.

② 이온 희석

원리: Ar 이온 빔은 샘플을 특정 경사각(5~30°)으로 폭격하여 샘플을 얇게 만듭니다.

대상: 세라믹이나 금속간 화합물과 같은 취성 재료는 일반적으로 10시간 이상이나 그 이상의 오랜 시간이 필요하며 작업 효율성이 낮습니다.

적용 조건: 이온 희석법은 다양한 재료에 적용될 수 있습니다. 희석 공정 중 온도가 높기 때문에 열에 민감한 재료에는 적합하지 않습니다.

집속 이온 빔(FIB)은 전기 렌즈를 사용하여 이온 빔을 매우 작은 크기로 집중시키는 미세 절단 도구입니다. 현재 상용 시스템에서 사용되는 이온 빔은 액상 금속 이온 소스이며, 금속 재료는 갈륨(Ga)입니다. 갈륨은 녹는점이 낮고 증기압이 낮으며 산화 저항성이 좋기 때문입니다. 액체 금속 이온 소스에 외부 전기장(Suppressor)을 사용하면 작은 액체 갈륨 팁을 형성할 수 있으며, 음의 전기장(Extractor)을 사용하여 팁에서 갈륨을 당겨 갈륨 이온 빔을 방출할 수 있습니다. 빔은 전기 렌즈로 집중되고 이온 빔의 크기는 일련의 조리개 변화에 의해 결정될 수 있습니다. 두 번째 집중 후 시편 표면으로 향하게 되고 물리적 충돌을 사용하여 절단 목적을 달성합니다.

④ 초박막 슬라이스

초박절편은 전자현미경 관찰에 사용되는 절편입니다. 전자가 조직을 투과하는 능력이 낮기 때문에, 전자현미경 관찰에는 초박편(일반적으로 80~100nm 두께)이 필요하며, 주로 생물학적 시료, 고분자 재료 등을 준비할 때 사용됩니다.

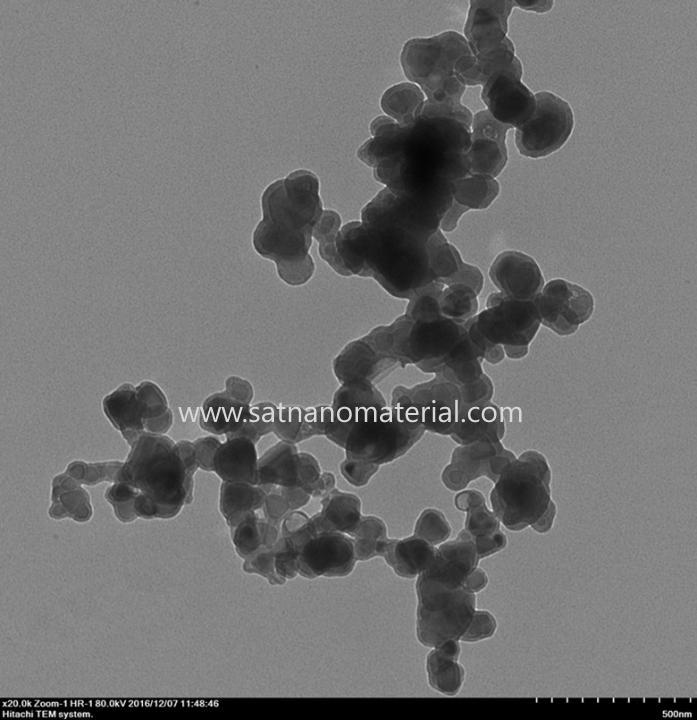

마이크로 나노 입자

, 고무 및 기타 재료.

위성 나노 최고의 공급업체입니다 나노파우더 그리고 중국에서 미크론 분말을 생산하는 우리는 좋은 품질의 제품과 생산 정보를 공급할 뿐만 아니라 최고의 애프터 서비스도 제공합니다. 문의 사항이 있으시면 언제든지 저희에게 연락해 주십시오. admin@satnano.com